Amasa Delano at the Lima Mint, 1805

Last weekend I finished reading Greg Grandin’s The Empire of Necessity: Slavery, Freedom, and Deception in the New World (2015), which is an elaborate retelling of the true history that inspired Herman Melville’s famed novella “Benito Cereno.” Originally serialized in Putnam’s Monthly in the fall of 1855, Melville’s story is a fictionalized account of an 1805 encounter between a New England sealing vessel and a Spanish ship that had been taken over by the slaves it was carrying near Santa María Island off the coast of Chile.

The drama of the historical episode and Melville’s story derives from the fact the American captain Amasa Delano boarded the disordered Spanish vessel without knowing that the slaves had seized it. He spent most of a day rendering aid and touring the ship with its captain, Benito Cerreño and his ‘personal slave’ Mori, who never left his ostensible master’s side. Although some strange behavior arouses suspicion, it is not until he was departing that the ruse was revealed when the Spanish captain desperately leapt from his ship into Delano’s departing long boat screaming about the rebellion. Although it quickly cut its lines in an attempt to escape, Delano dispatched two heavily-armed boats that violently retook the vessel from its captors, killing both slaves and some of the surviving Spanish crew in the process.

Delano’s rather laconic account of the affair and documents relating to it were published in his 1817 memoir, which formed the basis for Melville’s story. Grandin’s book ably places the whole episode in the larger context of New World slavery and offers a narrative that effectively intertwines the history of Spanish America, African slavery, and the United States. Although the grand themes lead to a few rather ponderous passages, Grandin’s extensive research and fine writing ensure that Empire of Necessity is a rewarding read.

In any case, it also led me to peruse the book that Delano produced about a decade after he returned to the United States. Narrative of Voyages and Travels in the Northern and Southern Hemispheres (1817) is a six-hundred-page tome that chronicles his three voyages around the globe, the last of which was as captain of the Perseverance (1803–1808). The book provides a wonderful, if occasionally disturbing (check out the passage where some of the crew drowns), picture of the early China trade and the Pacific maritime world of the late eighteenth and early nineteenth century. As usual here on Pocket Change, we are exploring Delano’s Narrative because of a largely unknown numismatic angle, one that shines a light on the workings of the Lima mint. Part of the reason that Delano and his crew risked life and limb to recapture Cerreño’s ship was that they expected a reward for their actions. When colonial officials in Santiago failed to satisfy Delano’s demands, he sailed for Lima in the fall of 1805 in the hope of getting a hearing with the Viceroy of Peru, Gabriel de Avilés Itúrbide. Avilés took a liking to Delano, but any settlement required extensive negotiations, and during the interim he was given free rein of the city.

One of the places Delano visited was the Casa de Moneda de Lima, the city’s mint, which was established in 1568 to coin the silver that was pouring out of the Peruvian Andes. The building that he visited, and which still stands today, was opened in 1758 after a violent earthquake destroyed the earlier structure. Delano began his tour in the area where the gold ore was processed. Here he observed slaves performing the toxic work of refining the gold ore by kneading the doughy mixture with their bare feet and separating out the gold with quicksilver or mercury. After the metal was melted and cast into bars, Delano continues:

After the ore is drawn off in this way in bars, according to the dimensions of the mould, they are taken to a room further to the right in which the grand water works are fixed; in this room were more than ten pairs of rollers arranged very much like those that sugar cane is run through in the West Indies, made horizontal, and gradually decreasing in space. The bars of gold and silver are run through, between these rollers, from one to the other, until they are laminated to near the thickness of a dollar, and the gold to that of a doubloon, having by that time the requisite width. By the time they are nearly reduced to a right thickness they are more than four feet long, the silver having a similar appearance to iron hoops. They are then taken to another room still to the right, and run through a plate which brings them to an exact thickness, at which time they are wide enough to cut out the dollar. After this they are passed under a sharp steel trepan of a roundish figure, hollow within, and of porportionable diameter to shape and cut the piece at the same time. This instrument is fixed at the lower end of a screw which is made with a very large worm; this causes it to descend very forcibly, and when the laminated bar is held under it, every time the screw is turned it comes down and cuts a piece out of the silver the exact size of a dollar; but when a gold laminated bar drawn to a proper thickness, is placed under it, the screw is supplied with another instrument to pierce out a piece the exact size of a doubloon. They are next milled by means of running them through a machine that is only the thickness of a dollar, which is confined edge ways, so that by turning a crank it will roll the dollars through, putting at the same time the mill on the edge.

With the edges of the planchets now serrated or milled, the blanks were weighed, corrected as needed with pins, and then moved into the coining room. There a bronze stamping press was used to produce the final product. The engraving below is from instructions issued in the 1770s by the mint in Potosí, but the machinery used in Lima was similar, if not identical.

Delano described the final step of the coining process as follows:

The master set the people to work at coining dollars and doubloons, to shew me the last process, as I had previously seen all but that. The method is, the two impressions are cut on two pieces of steel, about the size of a blacksmith’s sledge hammer, and not very unlike it in shape, the impressions being cut on the face of each; these two pieces are fixed, one in a frame made of wood and iron on the ground, fastened very strongly with screws, with the impression upwards; the other piece is fixed at the lower end of a large screw, five inches in diameter and four feet long, with the impression side down, and placed directly over the one that is fixed on the ground, all parts of the machine being framed together in a remarkable strong manner. An iron tiller, large bar, is put on the head of the screw in the same manner a boat’s tiller is put over the head of the rudder, the hole for the screw being in the middle of the tiller, which is twelve feet long, having each end of it loaded with about fifty weight of lead and ropes four or five feet long fastened to each end for the men to poll by, who sit down and take hold of the ropes, being from five to seven in number. The man who puts the dollars under has a hole sunk on one side of his work for him to sit in. When the men were all called to their stations and a thousand dollars emptied near the work, the master stepped to the pile and took a handful which he brought to me to inspect, and shewed me where the pins were put in to make up the weight, which were very plain to be seen. One man who stands up at one end of the tiller throws it back and raises the screw. A piece of wood was taken out from between the two impressions that serves to keep them apart and a dollar put under in its stead, on which the screw is turned forward with the full strength of the men placed at the tiller, by which it comes down with incredible force on the dollar. The man at the opposite end of the tiller then heaves it back and raises the screw. The dollar is brushed off by means of a piece of iron twelve inches long, of the thickness and width of an iron hoop, which he constantly holds in his hand, and another dollar is put under. They were handed to me to see how fair and deep the impressions were made, and how completely the pins were pressed in; but I could see on some of them where the pin was. This may often be seen in Spanish dollars, if closely inspected. After showing me as many as I wished to see, they set the screw to work as fast as possible. They could easily finish fifteen in a minute, or one in four seconds. The process with doubloons is the same as with dollars. The pressure of the screw when it comes down on the coin I should imagine to equal a great number of tons, perhaps one hundred.

The silver dollars that Delano observed being minted were 8-real coins or ‘pieces of eight,’ which circulated throughout the Americas. Below is an 1805 specimen from the Lima mint.

ANS 1967.113.728

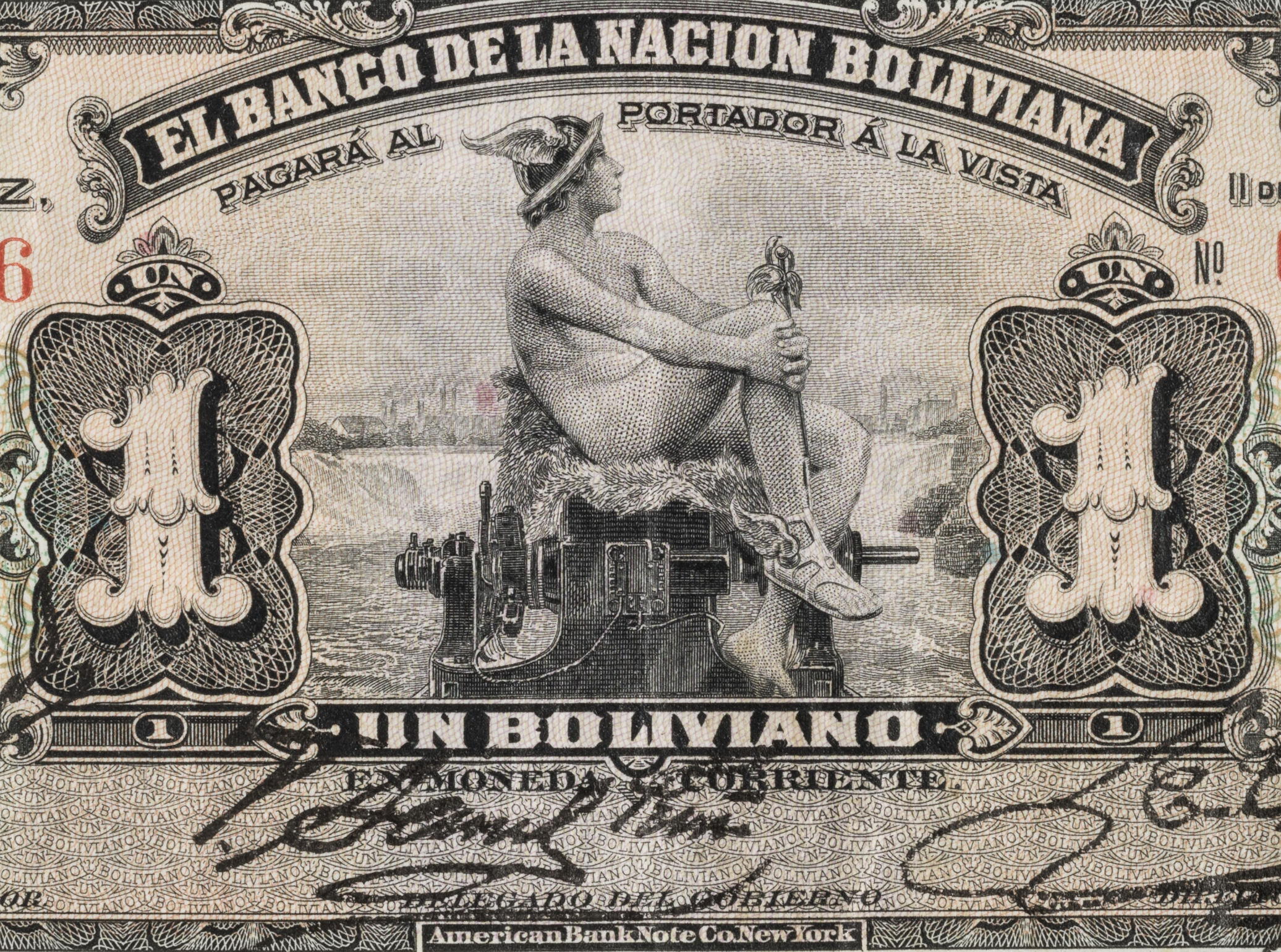

These were known as Spanish dollars in the United States, and they were undoubtedly the most common silver coin there at the time. Indeed, after 1804 the US Mint at Philadelphia was not even producing silver dollars. The doubloon that Delano refers to was the colloquial name for a gold coined valued at two escudos.

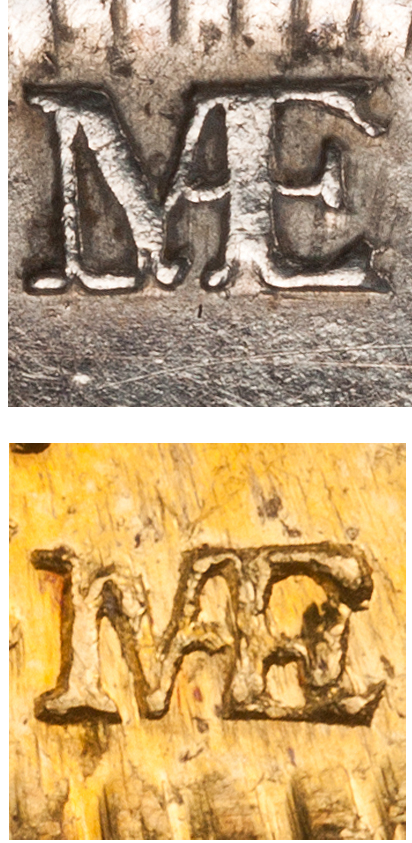

This example dating to 1800 is also from the Lima mint, which you can tell by the mintmark on the reverse. The mark changed over time but in that era it resembled the overlapped letters M and E. The Lima mint continued to strike coinage in this mold until 1821, when General José de San Martín declared Peru’s independence from the Spanish Empire. In 1822, new 8-real coins were struck with the legend PERU LIBRE and a obverse that featured the allegorical figures of justice and virtue. The mint remains in operation today, and for a fine article with many photographs detailing its history and environs see Glen S. Murray’s piece in The Numismatist (July 1980).

Delano’s four-page account of his 1805 visit stands out as perhaps the most complete contemporary account of the workings of the Lima mint in English. The full text of the passage is transcribed below the fold and is well worth reading for the wealth of detail it provides. One final numismatic note to his narrative concerns the eventual reward for the “rescue” of the Spanish ship. When Delano returned to Boston in late July 1807, he received a letter and a medal from the King of Spain, Charles IV, for his service. Delano described it as a “gold medal, having his majesty’s likeness on one side, and on the other the inscription, Reward of Merit.” The ANS has one of these medals in silver, and the gold version was no doubt of a similar, albeit smaller, design.

Excerpted from Amasa Delano, Narrative of voyages and travels in the northern and southern hemispheres: comprising three voyages round the world, together with a voyage of survey and discovery, in the Pacific Ocean and Oriental islands. (Boston: Printed by E.G. House for the author, 1817), pgs. 499-503.

The next curiosity here, that is worthy of mentioning, is the mint; which I visited and was shown every thing worth my attention in it. Two or three gentlemen accompanied me to see it, first having sent to know when we could be admitted, and the answer being returned appointing the day. When we went we were received with every degree of attention that could be shown. The master or conductor went with us over all parts of it, and shewed us all that was worthy of seeing, and explained every thing to my sati-faction. The building forms a square, one part of it fronting on the street. It has a strong wall on all sides of it, which forms a large square that is about one hundred and fifty feet each way. The gate is in the middle of the front side. We entered a row of buildings on the left hand after passing through the gate, in which the process of refining and separating the ore is performed; and as we proceeded on the left hand side, we came to where they were melting and casting gold and silver in moulds. It was cast in a proper shape to be drawn down cold. The process with the gold which was performed in my presence, was by bruising the ore fine with mauls, and then wetting it with some liquid, and working it over in the same manner as lime mortar is prepared in this country. This is done on the floor of the room, which was all paved with smooth stones, or bricks. This labour is done by negroes, who tread it over with their feet and kneed it like dough, after which they put quick silver amongst it, as I was informed, which separates the ore from the other metals that are mixed with it. It had the appearance as they worked it, of yellow mortar, or dough. After it was separated, it was cast into ingots or bars. The silver is separated previous to its being brought to the mint, and cast into pigs that weigh from eighty to one hundred and sixty pounds each. Many tons of these bars I saw piled up like cord wood. [pg. 499]

There was another method by which I saw them separate gold dust (so called,) which is by patting it into a little trench, that runs through one part of the mint. It is made serpentine, and is about one foot wide and two feet deep, with a little descent. Its sides and bottom are made as smooth and even as possible with stone and lime cemented together. In each of the turns of this trench a small ragged iron wheel is sunk, like the sunk wheel of a watch, in the cement at the bottom of the trench. This wheel has a shaft, or spindle in the middle, which comes above the top of the trench, and has another wooden horizontal wheel on the top of this spindle; to which were fixed bands that were brought from the barrel of a large wheel, which being put in motion moved all the small ones. The gold dust sand, and all together was taken up, was put into the upper part of the trench, and a gate hoisted that set the large wheel going which moved the horizontal sunk wheels. The water running likewise through the trench carried the dust down, and at every sunk wheel it got a scouring; and by the time it had passed through the the trench, the sand and other particles of matter lighter than gold were swept away, and the gold dust left in the basins formed for the ragged wheels to move in.

The next process is the melting of the metal. The method for this was to have crucibles made of a kind of clay, which will stand fire. These are made in the form of a tub as large as a half hog-head with the top a little contracted, which were suspended by axles fixed to their sides and placed in a frame similar to the method that blacksmiths hang their bellows: by which means they can tip them backwards and forwards. They have an iron crutch, or brace, which hooks into two eyes like crane eyes, put into the side of the crucible for the purpose of commanding it. The crucibles are filled with charcoal, after a fire being kindled in them, and two or three hundred weight of gold or silver put on the coals. Two large bellows of a curious construction, worked by hand, were brought up to the front of the crucibles, and their pipes introduced into two holes made for that purpose, which blows the fire with great force. The fire is constantly fed with coals until the ore is sufficiently melted for casting. Whilst it is running into the moulds, it [pg. 500] [can]not be destinguished, the gold from the silver, both being as red as blood. When the ore is sufficiently heated, the bellows is moved back by means of something similar to cogs or rollers; the crucible is then tipped backwards on account of the holes made for the bellows pipes, until the metal rises above the top of a little spout like that of a pitcher, but it will not run until it is touched with a small stick with a piece of cloth round the end of it and moistened with some kind of oil; this when touched to the spout where it is wanted the metal to run from, will flash in a blaze like powder, and immediately the ore will run in a small stream not much larger than a pipe stem, into moulds cut in small flat iron bars, about twenty inches long, one inch and a quarter wide, and half an inch deep, with wooden handles to them. After the ore is drawn off in this way in bars, according to the dimensions of the mould, they are taken to a room further to the right in which the grand water works are fixed; in this room were more than ten pairs of rollers arranged very much like those that sugar cane is run through in the West Indies, made horizontal, and gradually decreasing in space. The bars of gold and silver are run through, between these rollers, from one to the other, until they are laminated to near the thickness of a dollar, and the gold to that of a doubloon, having by that time the requisite width. By the time they are nearly reduced to a right thickness they are more than four feet long, the silver having a similar appearance to iron hoops. They are then taken to another room still to the right, and run through a plate which brings them to an exact thickness, at which time they are wide enough to cut out the dollar. After this they are passed under a sharp steel trepan of a roundish figure, hollow within, and of porportionable diameter to shape and cut the piece at the same time. This instrument is fixed at the lower end of a screw which is made with a very large worm; this causes it to descend very forcibly, and when the laminated bar is held under it, every time the screw is turned it comes down and cuts a piece out of the silver the exact size of a dollar; but when a gold laminated bar drawn to a proper thickness, is placed under it, the screw is supplied with another instrument to pierce out a piece the exact size of a doubloon. They are next milled by means of running them through a machine that is only the [pg. 501] thickness of a dollar, which is confined edge ways, so that by turning a crank it will roll the dollars through, putting at the same time the mill on the edge. The next process is the weighing; the person who performs this has a little square box containing silver pins that are no longer than the thickness of a dollar, and of different weights and sizes; the dollars are thrown one by one into the scales, but seldom any of them are too heavy, when they are they generally pass them without notice, but if any are too light a pin is thrown into the scale, which brings it to the standard weight; the dollar is then put under a screw that has a pointed instrument in the end of it, which is screwed down and pierces a hole in the dollar sufficiently large to receive the pin; then it is placed under another screw, with a smooth end, which completely fastens the pin in the coin; they are then passed into another room and scoured. That process is performed by putting one or two bushels of them into a wooden bowl made for that purpose and lime juice poured into it sufficient to wet the dollars; when a man, supplied with strong leather gloves to prevent hurting his hands, rubs and scours until they become bright as silver can possibly be made. After this operation they are passed to another room, which is the last in the square, and the first on the right hand on entering the gate, which is the apartment where all the money is coined.

The master set the people to work at coining dollars and doubloons, to shew me the last process, as I had previously seen all but that. The method is, the two impressions are cut on two pieces of steel, about the size of a blacksmith’s sledge hammer, and not very unlike it in shape, the impressions being cut on the face of each; these two pieces are fixed, one in a frame made of wood and iron on the ground, fastened very strongly with screws, with the impression upwards; the other piece is fixed at the lower end of a large screw, five inches in diameter and four feet long, with the impression side down, and placed directly over the one that is fixed on the ground, all parts of the machine being framed together in a remarkable strong manner. An iron tiller, large bar, is put on the head of the screw in the same manner a boat’s tiller is put over the head of the rudder, the hole for the screw being in the middle of the tiller, which is twelve feet long, having each end of [pg. 502] it loaded with about fifty weight of lead and ropes four or five feet long fastened to each end for the men to poll by, who sit down and take hold of the ropes, being from five to seven in number. The man who puts the dollars under has a hole sunk on one side of his work for him to sit in. When the men were all called to their stations and a thousand dollars emptied near the work, the master stepped to the pile and took a handful which he brought to me to inspect, and shewed me where the pins were put in to make up the weight, which were very plain to be seen. One man who stands up at one end of the tiller throws it back and raises the screw. A piece of wood was taken out from between the two impressions that serves to keep them apart and a dollar pot under in its stead, on which the screw is turned forward with the full strength of the men placed at the tiller, by which it comes down with incredible force on the dollar. The man at the opposite end of the tiller then heaves it back and raises the screw. The dollar is brushed off by means of a piece of iron twelve inches long, of the thickness and width of an iron hoop, which he constantly holds in his hand, and another dollar is put under. They were handed to me to see how fair and deep the impressions were made, and how completely the pins were pressed in; but I could see on some of them where the pin was. This may often be seen in Spanish dollars, if closely inspected. After showing me as many as I wished to see, they set the screw to work as fast as possible. They could easily finish fifteen in a minute, or one in four seconds. The process with doubloons is the same as with dollars. The pressure of the screw when it comes down on the coin I should imagine to equal a great number of tons, perhaps one hundred. When we had gone all over this remarkable building, I asked the master many questions, which he answered with frankness, seemingly pleased to inform me of any thing that I might wish to know. On taking leave of the mint, I asked the master how much money they commonly coined in a year in that mint. He informed me that they coined from six to eight millions of dollars value in gold and silver, and also that the mint in Mexico coined from fifteen to twenty millions, and St. Jago, in Chili, from one and a half to three millions, which was all the money that was coined in these three kingdoms. He told me that the bullion I saw belonged to different [pg. 503] people, and was brought to be coined in the same manner as corn is carried to a mill to be ground, and that as fast as it was coined it was taken away by the respective owners. He gave me much information concerning the regulations of the mint too numerous to be here related. Almost all the heavy work was done by water. There seemed to be as many wheels and bands going in it as in one of our cotton factories. Water works can be carried on in Lima with as much convenience as in any place I ever visited. The reason I had so much attention paid me at Lima was on account of the different services I had rendered, as many great men think it an honour to notice a person who has done well by his fellow creatures. This cause may be assigned for the viceroy’s noticing me, and among other marks of respect, gave me liberty to examine any curiosity in or about the city; as also to visit the prisons, to see any person in them I chose, and take out of confinement any Englishman or foreigner, and take him on board my ship. Many similar favours were granted me during my stay at that place.